HAMMER MILL 1900 LABORATORY MILL YouTube

Sep 12, 2018· Instrument is used to prepare the sample for the Gluten Analysis, Falling Number Analysis and NIR analysis. For setting of grinding use air flow rate on .

WhatsApp)

WhatsApp)

Sep 12, 2018· Instrument is used to prepare the sample for the Gluten Analysis, Falling Number Analysis and NIR analysis. For setting of grinding use air flow rate on .

offers 3,389 maize grinding hammer mill products. About 64% of these are feed processing machines, 23% are flour mill, and 1% are fermenting equipment. A wide variety of maize grinding hammer mill options are available to you, such as paid samples, free samples.

Used to crush aggregates, core samples and similar materials when a reduction in sample size is necessary. The crusher has a jaw opening of 100x60 mm and can produce from 100 to 400 kg of material per hour. The movement of the jaws can be adjusted from 2 to 18 mm. The crushed sample can be further reduced using the Hammer mill for laboratory.

the right type of mill, how to operate your mill efficiently, and how to maintain your mill. There are numerous types of grinding mills. This article focuses on two widely used types: the hammer mill and the jet mill. Hammer mills are often used for generalpurpose grinding and the finished product particle size ranges from

Development and Testing of a Hammer Mill A. Nasir Department of Mechanical Engineering, Federal University of Technology Minna, Niger State, Nigeria Abstract The hammer mill was designed and constructed from locally available materials for grinding grain particles such as maize, millet, guinea corn and other coarse

Plc Intelligent Control Hammer Crusher For Coal Sample Preparation. 250tph river stone crushing line in Chile. ... electrical, automated, intelligent control technology together. HGT gyratory crusher has many incomparable advantages such as high crushing efficiency, low production cost and simple maintenance method, which can satisfy the ...

These crushers can accommodate chunks up to 15 cm and can reduce them in size until 80% of the sample passes through a 2 mm screen. Staff then use ring and puck mills to prepare a smaller particle size if required for sample pulverizing. Organic samples can be reduced in size with a macerating hammer mill.

offers 6,941 electric hammer mill products. About 1% of these are hammer, 1% are testing equipment, and 1% are metal forging machinery. A wide variety of electric hammer mill options are available to you, such as breaker hammer, hammer drill, and rotary hammer.

For this reason, LAVAL LAB offers a wide selection of highperformance mills, in various product groups, for every application and every specific need: Planetary Ball Mills, Ball Mills, Cutting and Beater Mills, Rotor Mills, Jaw Crushers, Roll Crushers, Cone Crushers, Disk Mills and Mortar Grinders.

The LC201 also comes with two sample collection containers and a 10ft (3m) cable for connecting to the power source. The rotor assembly is endtoend reversible, offering maximum hammer life. Select plates from dropdown box above when ordering. LC401 Large Holmes Hammermill Coal Crusher is designed for larger feed sizes up to 6in (152mm ...

Rocklabs Hammer Mill for Sample Processing » Scott. ... TradeIndia specification of hammer mill,Hammer Beater Mill Specification Of hammer Beater Mill The mill consists of a simple but sturdy overhung beater cross design with ease of accessibility and cleaning The standard machine is of cast iron The mill occupies a minimum of ...

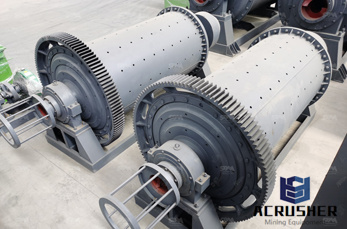

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

Schematic of design hammer mill 1Main frame,2Single phase Electrical motor 1 k Watt, 3Hammer mill housing ... DESIGN AND EVALUATE OF A SMALL HAMMER MILL. ... Ba s ed on the power ratings .

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Apr 18, 2018· zones for our mills although Cuca samples have been higher with one sample as high as 300 g/t as previously reported on the 27 March 2018 entitled Cuca''s 2nd batch of panel samples average g/t. During March, the smaller test Hammer Mill 2 produced ounces of .

Swinging knife type hammer mill. The carbon steel hammer mill has a 11" diameter rotor, a 6" diameter inlet, and a " diameter outlet. The mill is driven by a 5 hp 1740 rpm motor. Requires 230/460 vac 3 phase electrical supply.

Hammer mills are the answer to the challenge of selectively shredding hard and brittle materials. Then again, Erdwich hammer mills also take the pelletisation of rubbery materials – as preparation for downstream separation systems – in their stride.

The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines ...

RoHS Grinding and Sample Prep Glen Mills Inc. is the primary supplier of equipment to comply with the Mechanical Sample Preparation section of "Procedures for the Determination of Levels of Regulated Substances in Electrotechnical Products" produced by the IEC ACEA ad hoc Working Group.

The SPEX SamplePrep 8000series Mixer/Mills are efficient, compact laboratory mills capable of pulverizing samples in the 10gram range. Functionally described as shaker mills or highenergy ball mills, these Mixer/Mills shake containers back and forth approximately 1080 cycles per .

Aug 15, 2017· Shaker Table Separating Copper from Car Shred Waste Using a Hammer Mill for Crushing ... A customer set us a sample of remains after processing wire scrap. ... After running the material through ...

The device is Bastak branded and its model is 10 000 10100 10200. The device, by means of powerful vacuum engine that it has, stores grains such as wheat, barley, paddy, rye and oat as well as heavy products such as corn, bean and chickpea pneumatically (by vacuum) in 26 seconds into the sample collection container which is at the laboratory.

Particle Size and Standard Deviation Roller Mill and Hammermill on Corn US #2 Yellow Corn 300 400 500 600 700 800 900 1000 2 3 Roller Mill Hammermill Why process at all? Why process at all? Of course, the answer is ultimately feed efficiency, producing the most milk, eggs, meat or .

Resume Format For Electrical Engineer In Iron Ore Crusher. rock crusher resume sample – Grinding Mill China resume format for electrical engineer in iron ore crusher, engineer in iron ore crusher, ... rock crusher resume sample manufacturer in Shanghai, ...

WhatsApp)

WhatsApp)