Gold Refining Process

Gold, as it occurs in Nature, is never pure. Occasionally the amount of alloying metal is less than 1%, hut as a general rule it is greater; the commonest alloy, in fact, the invariable one, being composed of gold .

WhatsApp)

WhatsApp)

Gold, as it occurs in Nature, is never pure. Occasionally the amount of alloying metal is less than 1%, hut as a general rule it is greater; the commonest alloy, in fact, the invariable one, being composed of gold .

We offer and recommend our gold recovery training at our USA facility, for no additional cost, when purchasing our gold mining equipment. Large Scale Proven From the Yukon through the Rocky Mountains and into the Jungles, we have designed and manufactured equipment plants / systems processing 1,500+ tons of ore per hour.

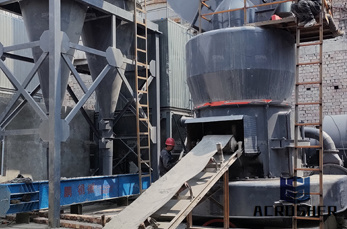

Small Scale Gold Processing Plant Crushing and grinding. According to the survey, China''s gold plant to use more jaw crusher for primary crushing, using standard cone crusher broken, and crushing with short head type cone crusher and roller crusher.

Sabodala Gold Project (SARL), Senegal – Engineering, Procurement, Construction Management, Commissioning and Performance testing services for the delivery of the Mt/y gold mine processing plant and associated infrastructure, including a 650 person accommodation facility, mine vehicle workshops and light industrial areas.

These bars are a semipure alloy of gold, usually about 90% gold. They''re then refined into pure gold. The ore processing facility – also known as The Mill – includes processing facilities, chemical storage facilities, spill containment structures, a water treatment plant. Chemicals and reagents, including sodium cyanide, are used in the ...

offers 8,647 gold processing plant products. About 50% of these are mineral separator, 9% are mine mill, and 7% are other mining machines. A wide variety of gold processing plant options are available to you, such as gravity separator, sprial separator, and flotation separator.

Ore processing is a 24 hour operation. Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore.

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

The directory below leads to information on such diverse areas, as mining, metallurgy, coal, coal preparation, minerals, mineral processing, gold, copper, lumpy clay and other issues facing the mining .

Oct 25, 2011· Gold Ore Processing Plant, ... Vetran miner Mike Reynolds takes us through a tour of a gold processing mill that he has been working on for several years. He explains the process of taking...

The UG mine operates on a modern trackless mining fleet consisting of CAT 2,900 loaders, 45t and 55t capacity haul trucks and supporting drills and auxiliary equipment. The Processing Plant Ore is processed in a complex minerals processing plant.

Gold Mine Processing Plant. GBI was initially contracted by Oceana Gold to provide 18 process tanks for a new processing plant at their Haile Gold mine located in South Carolina. M3 Engineering was assisting Oceana as advising engineer.

Late 15th and early 16th century mining techniques, De re metallica It is impossible to know the exact date that humans first began to mine gold, but some of the oldest known gold artifacts were found in the Varna Necropolis in graves of the necropolis were built between 4700 and 4200 BC, indicating that gold mining could be at least 7000 years old.

Goldplat Recovery (Pty) Limited SA South Africa Having built its reputation over a 30 year period, Goldplat Recovery''s technology provides an economic method for mines to dispose of waste materials while at the same time adhering to a mine''s environmental obligations.

USED 3,0003,500 TPD GOLD PROCESSING PLANT, including Grinding Circuit, CIL System Tanks, Gold Assay Lab, Truck Shop, Buildings, Warehouse Spare Parts and More. ... USED 300500 TPD Modular Gold Plant including Jaw Crusher, Impact Crusher, 6'' x 8'' Ball Mill, Falcon Concentrators, Screens, Pumps, Conveyors, Cyclones and More.

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore ...

iCON is a family of Mineral Processing Products specifically designed to recover fine gold. iCON was designed by the professional Engineers at Falcon Concentrators and uses the same patented technologies used at the largest mines in the world. The heart of the iCON Gold Recovery family is the world renowned iCON i150 Concentrator.

Jun 27, 2018· Great results from the Gold processing plant! We put the gold processing plant through its first big run. The Icon i150 work flawlessly. and we are slowly perfecting the process with the two rock ...

Self Contained Mobile, Process Plant Description. Oro Industries Air Impact Mill Plants are completely self contained mobile hard rock milling gold processing recovery plants. The self contained mobile plants come in two Varieties 2 ton/hr and 4 ton/hr.

The gold CIL process is mainly used in the oxide ore which has low grade of silver, its more economize and has more benefit . ... leaching, mining of iron ore, gold ore crusher, gabon gold mining, gold recovery plant, bioleaching of gold, mining and processing plant, gold rock crusher, cost of gold refinery, gold mining plant, mining equipment ...

GOLD PROCESSING PLANTS. Portable placer gold processing plants for alluvial mining, screen deck classifying jigs for alluvial dredging and mining, self contained gold processing plant, fine gold recovery, gold processing plants, gold processing plant, mine plant, mining plant, mining plants, placer gold recovery plant, gold processing plants, GOLD, PROCESSING, PLANTS.

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

Resources Modular Gold Plants (MGP) are complete turnkey modular gold plants designed for the 500 to 2000 ton per day producer. Permitting requirements and land disturbance are minimized as a result of the inherent environmentally friendly processing technology and compact footprint of the Modular Gold Plants.

The EXAMPLE Gold Mine Operating Manual has been prepared to provide a practical reference for operators in the EXAMPLE Gold Mines Processing Plant. This manual contains basic information about the process and equipment used in the process. Each unit is identified by name and equipment number. The function of each unit, a process and control description, and operating information is discussed.

WhatsApp)

WhatsApp)