(PDF) SIZE REDUCTION BY GRINDING METHODS

Grinding Process: Size reduction by crushing has a size lim itation for the final products. ... This is an important aspect in Geoexploration and industrial economic geology. The report provides ...

WhatsApp)

WhatsApp)

Grinding Process: Size reduction by crushing has a size lim itation for the final products. ... This is an important aspect in Geoexploration and industrial economic geology. The report provides ...

Coolants and their Role in Grinding. ... amply demonstrate the importance of friction, cooling ... It has an advantage over traditional grinding process to reduce the number of set up changes ...

Aug 29, 2019· Precision grinding is used for a variety of products, both large and small, as this process has the ability to accommodate exact individual specifications. This accuracy is important in industries that have little margin for error, for parts such as: components for medical devices, scientific instruments, and aerospace mechanisms.

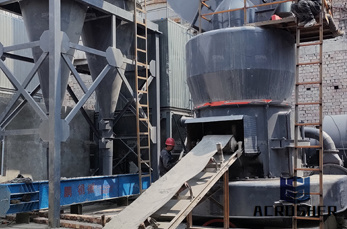

The importance of grinding table in vertical roller mills. | Editor: The vertical roller mill is a grinding equipment commonly used in the cement industry. The vertical grinding process is completed by a set of grinding devices, namely grinding roller and grinding table. The material is ground into powder between the grinding rollers ...

Aug 25, 2015· Grinding wheels are nothing but Multipoint cutting tools, which consists of multiple cutting edges. The components of a grinding wheel is Abrasive Grain (Conventionally Silicon Carbide, Aluminium Oxide are used), Bonding Material (Resinoid, Rubbe...

Difference between grinding and milling The abrasive grains in the wheel are much smaller and more numerous than the teeth on a milling cutter. Cutting speeds in grinding are much higher than in milling. The abrasive grits in a grinding wheel are randomly oriented . A grinding wheel is selfsharpening.

importance of grinding process – Grinding Mill China Grinding Process – Winterthur Technology. As a general rule, grinding tools comprise a basic tool body and an abrasive coating.

The importance of grinding. Among the various stages of the pelleting process grinding is essential for pelletizing, because it allows to create a homogeneous mixing and to reduce the volumes. SHARE THIS. Particle size reduction is the first step in the feed manufacturing process and, in terms of pellet mill operations, has a great ...

Grinding is a subset of cutting, as grinding is a true metalcutting process. Grinding is very common in mineral processing plants and the cement industry. Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension.

May 07, 2018· Watching important parameters allows you to improve profitability by making necessary changes. Before getting into the four categories that influence grinding efficiency, it''s important to know how the grinding process works. When you''re using a grinding machine, three interactions are happening at the same time: cutting, plowing and sliding.

Oct 25, 2011· Because the grinding process creates a lot of heat, flood coolant is most appropriate. However, it is equally important that the fluid be delivered where it is needed the most: at the point of cut. "The application [method] of the fluid is very important; it should apply the fluid to the interface where it is needed the most," said Foster.

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

gypsum is added to cement in grinding process CODEP. importance of adding gypsum to the clinker before final grinding Feb 11, 2014 purpose of adding gypsum in the final cement grinding gypsum for grinding cement . importance of gypsum in limestone grinding

Dec 16, 2019· To begin with, you can attempt the dry grinding process and then end with the wet process to clean and finish the floor. Concrete Floor Grinding. Importance of Floor Grinding. The concrete beneath the floorboards can be uneven or rough. Installing various flooring on top of it can be a tough task. With floor grinding, you are able to get a ...

Grinding is the first step of mechanical material removal. Proper grinding removes damaged or deformed surface material, while limiting the amount of additional surface deformation. The goal is a plane surface with minimal damage that can easily be removed during polishing in .

Grinding Process Previous Next In the previous chapter, the various "laws" of comminution which have been propounded have been studied in relation to the physical process of size reduction and to the available results of experiments into the fracture of homogeneous and heterogeneous materials by impact and by slow compression.

Grinding machines are used for this purpose to produce parts of identical shape, size and finish. Chip Formation. In chip formation process materials are cut through mechanical means by using tools like milling cutters, saws and lathes. It is an integral part of the engineering of .

J. Carvill, in Mechanical Engineer''s Data Handbook, 1993. Grinding machines. Grinding machines produce flat, cylindrical and other surfaces by means of highspeed rotating abrasive wheels. Grinding is a means of giving a more accurate finish to a part already machined, but is also a machining process .

grinding machines perform the dressing task automatically. The application of coolants to the grinding process is important. Coolants reduce grinding machine power requirements, maintain work quality, stabilize part dimensions, and insure longer wheel life. Coolants are either emulsions, synthetic lubricants or special grinding oils.

Name some important bonding materials used in grinding wheels. Vitrified bond, silicate bond, rubber bond, resinoid bond, shellac bond, metallic bond. ... Process to clean the periphery of the grinding wheels, and to remove the dull abrasives grains to smoothen the surface. To balance grinding wheels when out of roundness.

Importance of Stump Grinding. Tree removal is a detailed process that requires a high level of professionalism. A good number of people assume that tree removal is just cutting down the trees. Surprisingly, this is only part of the task and getting rid of the stump is even more difficult. It is no wonder that you will have some tree companies ...

Aug 19, 2019· The coolant and grinding wheel are equally important tools in the roll grinding process. One of the key factors in achieving and maintaining grinding quality and a safe grinding environment is water purity. Importance of Water Purity. Using contaminated water in a coolant mixture can cause a multitude of problems in roll grinding operations.

What is Fine Grinding? What is Fine Grinding? Fine Grinding is a batchmode abrasive machining process that combines the speed and aggressiveness of super abrasive wheels with accuracy of lapping kinematics to produce flat and parallel work piece surfaces.

Size Reduction by Grinding as an Important Stage in Recycling 275 for example, multiedge grinders characterized by low energy consumption, low noise level and good repeatability of grain classes [4, 13]. Cutting between two cutting edges is widely used in cutting mills, in particular for grinding of plastics and crosslinked elastomers [48, 3].

WhatsApp)

WhatsApp)