MANUFACTURING PROCESS OF STEEL SCRAP TO BILLET AND .

Apr 22, 2012· presents and edit by sunil mishra from j, saudi arabia

WhatsApp)

WhatsApp)

Apr 22, 2012· presents and edit by sunil mishra from j, saudi arabia

Uralmashplant began to produce the rollingmill equipment in thirties just after starting the plant. In 1935, the first rolling mill 800 was built for Chusovsky metallurgical works. The rolling mills, bloomers, special units and systems produced at Uralmashplant were

Steel Industry Systems with Integrated Mechanical and Electrical Control for Highquality Production and Energy Efficiency 160 and rising raw material prices in recent years. In addition to improvements to the quality of steel strip and reliability of operation, is also developing rolling equipment and control technologies

HOT ROLLING MILL PLANT FOR ROUND BAR (12311) [12311] Machinery International Corp North Branford CT sales COMPLETE MELT, CAST AND BAR ROLLING MILL PLANT [110650] National Machinery Exchange Newark NJ sales

125 Steel Rolling Mills jobs available on Apply to Metallurgical Engineer, Quality Assurance Auditor, Mechanic and more! ... Positions in Cold Rolling Mill and Bell Type Annealing. Steel plant in Canonsburg, PA, participate in the apprenticeship program. Who perform this type of work.

Apr 11, 2013· Contact Person: Mr. Manjit Singh (+91 98140 36118) Mr. Tajinder Singh (+91 98140 26108) AVTAR Foundry Workshop Road Mandi Gobindgarh 147 301 (Pb.)

Detailed Project Reports Profiles on Steel Rerolling Mill Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue

how to devlopment re rolling mill plant. crushing equipment is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and . Get Price . Steel Rerolling Mills .

Oct 01, 2015· D7 rolling mill for 20 tons/Hr. Do You Know ! How Are Steel Pipes Produced | Steel Pipe Manufacturing Process At The Factory Duration: 12:23. Machine New Channel 911,418 views

1 HOT ROLLING PRACTICE – An Attempted Recollection Saral Dutta. B. Tech. (Hons.), Executive Director, ISP RMD, SAIL (Retired) Rolling is a metal forming process in which metal stock is passed through a pair of rolls.

welcome message for steel mills in bangladesh authomatic re rolling mills for steel in bd Bangladesh Steel Re Rolling Mills Ltd IPO Form Prospectus 2015 Bangladesh Steel Re Rolling Mills Limited initial public offering (IPO) has been approved by the Securities Regulator Authority, Bangladesh Securities and .

BILLET The main raw material for this process is iron scrap. This scrap material is tested in lab for its various elements. Then the scrap is melted in electric furnaces ( ex. 5 Ton furnace, 20 Ton furnace etc.) The melted liquid is then poured...

Aug 21, 2016· The video shows the manufacturing process of TMT bars in India.

Raw materials of billet production are mild steel scrap, ferroalloys, directreduced iron, carburizers, decarburizers and fluxes additives. Bars are produced in fully automated ReRolling Mills. The Captive Power Plant of 12MW (synchronized with PDB grid) and .

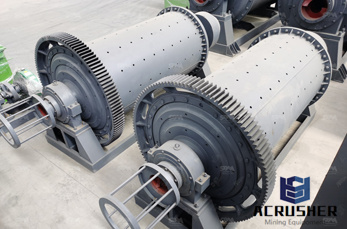

This rolling mill is designed for the production of steel balls that will be used into the ball mills for mines and cement factories. The plant is composed by a stand that transforms the round section bars into balls at the requested size.

The plant is a conglomeration of smaller units, each in itself complete and selfcontained. These constitute Coke Ovens, Coal Chemicals, Sinter Plants, Furnace, Steel Melting Shops, Continuous Casting Machine, Tonnage Oxygen Plants, Plate Mill, Hot Strip Mill, Cold Rolling Mill, other secondary mills, Captive Power Plants and a host of other 1708

COPPER COLD AND FOIL ROLLING MILL UCMMill and XMill Technology for thinner foil rolling. For copper cold rolling and foil rolling, several types of mill are selected according to the rolling process, thickness and materials to be produced. Our typical mill type is the UCMMill, which is suitable for rolling .

The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next process.

TMT Bar Manufacturing Plant Setup Machinery. Generally, you can establish a TMT bar manufacturing plant as a fully automatic manner. Depending upon the manufacturing technology and desired output, you must procure the rolling mill machinery.

As a lifecycle partner for coldrolling mills, Primetals Technologies offers complete solutions and support packages for coldrolling mills that extend from the initial investment idea, to mill planning, layout, engineering and construction, up to turnkey plant installations and fullscale plant modernizations.

The first ever steel mill was established in 1952 by the H Akberali Group of Industries as the "Bangladesh Steel Rerolling Mills (BSRM)". Located at Nasirabad, Chittagong, the plant formed reenforcing bars and structural sections.

Free Online Library: Development of a water treatment plant for a rollingmill train.(Report) by "Annals of DAAAM Proceedings"; Engineering and manufacturing Water treatment plants Design and construction Equipment and supplies

First rerolling mill was established in the year 1928 at Kanpur long before Independence of India. Gradually, rerolling mills came up in the limelight when concept of large scale steel plant was absent in the mind of the Government, but only large steel plants at that time was started to function at TATA, Jamshedpur in the year 1907.

Univac is a reliable Consultancy company, providing complete solution and unmatched steel plant advisory has played a significant role in development of Indian steel industry over the years and have acquired vast experience in conceptual planning, design and engineering of steel making, secondary metallurgy, continuous casting, Ferroalloys and steel ReRolling Mills.

WhatsApp)

WhatsApp)