Simulation of layout rearrangement in the grinding ...

In this study, a simulation of layout rearrangement in grinding/classification process was conducted to increase the throughput of an industrial plant.

WhatsApp)

WhatsApp)

In this study, a simulation of layout rearrangement in grinding/classification process was conducted to increase the throughput of an industrial plant.

Oct 29, 2019· Some stand mixers have a meat grinding accessory that can be attached to the main unit for small batch grinding. A handcranked meat grinder attached to a counter will work.

JKSimMet allows the user to: Build a graphicbased flowsheet of the processing plant; Assign machine criteria and model parameters to each plant case study; Simulate the effect of changes in operating conditions and flowsheets to predict product flows, size distributions, and other key performance metrics such as power draws

If you want to make cakes, gravies, and other foods, the weight and texture of the flour can make the difference between a flop and a success. In most cases, a grain mill will only grind one or two texture types. If you want smoother flour or lighter weight flour, you will need to use different grinding agents, or even a different mill altogether.

Jan 01, 2015· Batch grinding data using a Bond ball mill were collected to test the upgraded size reduction model. The model fits the batch grinding data well. The calibrated model from one ore sample was used to predict the breakage results for another ore with the measured ore characteristic parameters.

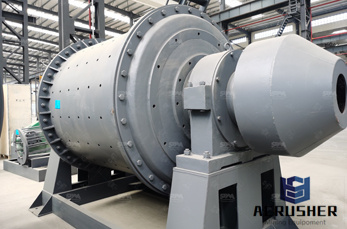

Grinding MillRaymond MillBall MillHammer Mill For . Shanghai Clirik Machinery Co. Ltd is a professional manufacturer of feldspar grinding mill, feldspar Raymond mill, feldspar ball mill, vertical mill, stone powder production line, feldspar grinding plant. Gcode Simulator GCode Qndirty toolpath simulator.

A formed grinding wheel with the corresponding angles enables the batch grinding of blocks. This makes perpendicular grinding as efficient as surface grinding when processing multicavity blocks. Profile dressing with swiveling roll dressers. The full spectrum of dressing devises with singlepoint diamonds both straight and profiling.

Jan 01, 1992· Experience with flotation simulation exercises, however, shows that it is very hard to predict accurately the performance of a particular circuit, given only ore specific information (eg rate constants) obtained from batch or smallscale continuous tests, to simulate a flotation circuit for design purposes.

Pour over grind size can be a bit tricky because the grind affects different variables in the brew. Not only does the grind size change the overall flavor, but it also helps determine the brew time. For most coneshaped pour overs (Hario V60, Kalita Wave, Bee house, etc.), mediumfine is the best setting to start experimenting with.

Grinding Turmeric. Since we make huge batches, we grind our turmeric in a flour mill. This makes things easier because the turmeric is ground smoothly and nothing is wasted. If you are making small batches, grind it in a spice or coffee mill. Sieve it and then grind the left overs again to a smooth powder.

A grinding model developed at ''El Pilon'' mine using JKSimMet (Version 4) was used to simulate three different milling designs. The objective of these simulations was to investigate a new design of the grinding circuit with an additional ball mill to increase both grinding throughput and fineness. The simulation results highlight that two ...

It can be used to determine the grinding power required for a given throughput of material under ball mill grinding conditions. It is a ''locked cycle'' test conducted in closed circuit with a laboratory screen. The Bond Ball Mill Work Index can be used in the design calculations and simulations using JKSimMet of a new grinding circuit.

Feb 14, 2020· (Grinding Beginner) Process 2 Polished Stone by Grinding Rough Stone. Give 2 Polished Stone to Ornella. Rocks can be found around Heidel, especially north of Heidel in the quarry area. It takes 10 Rough Stone per batch.

JKSimMet was developed over the past 35 years, incorporating ... simulate crushing, grinding and classification circuits. JKSimFloat has been developed over the past 20 years, incorporating outcomes from the JKMRC and other institutions around the world through the AMIRA International P9 project – The ... from the batch wise original Bond ...

The batch mill grinding equation can be described as being developed with respect to a control volume defined around the batch mill. ... 2014 James Didovich 2014 JKSimMet V6 4 JKSimMet Overview • JKSimMet is a package developed by the JKMRC/JKTech for the modelling and simulation of comminution circuits. ... was used to simulate wet grinding ...

This can include coolant, acid, alkaline, or etching wastewater compounds and rinses. It can also involve wastewater related to processes such as metal refining, machining, grinding, quenching, tube forming, stamping, tumbling, plating, electroplating, powder coating, and scrap metal recovery.

Generally, the feed charge is prepared from the material crushed in a jaw and/or roll crusher, and four to five batch grinding experiments are carried out sequentially to obtain about 95–99% ...

Feb 01, 2016· A specific energybased size reduction model for batch grinding ball mills was reported in a previous paper (Shi and Xie, 2015). A discharge function modified from the Whiten classification efficiency equation has been incorporated in the size reduction model to extend its applications from batch grinding to continuous operation.

A grinding model developed at ''El Pilon'' mine using JKSimMet (Version 4) was used to simulate three different milling designs. The objective of these simulations was to investigate a new design of ...

Jan 01, 2015· A particle size reduction model has been developed as the first component of an upgraded ball mill model. The model is based on a specific energysize reduction function, which calculates the particle breakage index, t 10, according to the sizespecific energy, and then calculates the full product size distribution using the t 10 –t n relationships and the masssize balance approach.

Here is a video of my homemade ball mill in operation with a brief explanation of all the parts and how I put it together. For detailed descriptions of all the parts, how I .

Feb 20, 2020· If using whole beans, grind the beans to a uniform consistency similar to regular table salt. Transfer the grounds into a filterlined filter basket, then place it in the drip machine. Swivel the water spout over the center of the grounds. Pour clean water into the back of the machine (not over the grounds) and press the on button.

The full scale model parameters were used to simulate the raw meal mill grinding circuit with the aid of JKSimMet Steady State Mineral Processing Simulator. ... to design and simulate grinding ...

Jul 31, 2014· Cement Grinding Optimization 1. CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email: Dr Walter Valery, Minerals Process Technology AsiaPacific, Brisbane, Australia Eugene Davis, Minerals AsiaPacific, Perth, Australia ABSTRACT The current world consumption of cement is .

WhatsApp)

WhatsApp)