Chapter 1 Fly Ash An Engineering Material Fly Ash ...

Oct 14, 2009· shows in animated form the fly ash processing by DIRK India at their Nashik POZZOCRETE plant.

WhatsApp)

WhatsApp)

Oct 14, 2009· shows in animated form the fly ash processing by DIRK India at their Nashik POZZOCRETE plant.

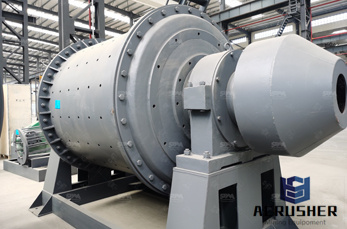

Material Processing Agglomeration. We offer disc pelletizers, pug mills, and pin mixers for all of your fly ash agglomeration needs, whether you are looking to dedust fly ash, or pelletize it for use in cement or as a soil amendment.. Thermal Processing. In addition to rotary dryers for drying fly ash, we can provide custom rotary kilns to accomplish the induration of fly ash for use in ...

The structural effects of fly ash may be more critical, but cosmetic concerns also affect its use in concrete. It is more difficult to control the color of concrete containing fly ash than mixtures with Portland cement only. Fly ash also may cause visual inconsistencies in the finished surface, such as dark streaks from carbon particles.

Philip Michael describes the process that recycles the waste from coalfired power stations into valuable industrial minerals.. Using a proven mining technique, the RockTron Beneficiation Process separates the waste fly ash components into 100 per cent recycled high performance products.

Mar 09, 2019· Char Solutions'' new MP618™ MultiProcess technology reduces loss on ignition (LOI), ammonia, activated carbon and moisture in fly ash. "The launch of the MP618 technology is a significant milestone for Char Solutions and a game changer for the beneficiation of fly ash," said Charles Price, President and CEO of Char Solutions.

Fly Ash Characteristics From WastetoEnergy Facilities and Processes For Ash ... The technology selection process begins with evaluating all plausible options, considering the quantity and quality of waste, the energy market options available, local environmental .

Coal fly ash was used as raw material for the preparation of ceramic materials by a conventional powder technology route. Powder compacts were made from asreceived fly ash, from calcined fly ash ...

In many cases, fly ash is coming from a storage pond and requires drying before it is ready for reuse or recovery applications. Unfortunately, fly ash drying is made challenging as a result of the dusty nature of fly ash. As such, dust suppression via agglomeration is often employed prior to drying.

Billions of tonnes of coalfired power station waste, called fly ash, are dumped in long term landfill sites worldwide. RockTron has developed a commercial mineral processing solution for this massive and growing environmental problem, transforming fly ash into valuable ecominerals on an industrial scale, with no waste stream.

Fleets Technology. ... SEFA Building Fly Ash Recycling Plant ... fly ash from other Santee Cooper electric generating stations also may be transported to the Winy Station site for processing.

strength by substituting a portion of the cement with coal fly ash in the concrete mixture (EPA, 2005). The next major project was utilization of over 120,000 metric tons of fly ash in the Hungry Horse Dam in 1948 (ARTBA, 2011). Fly ash then started to be used in .

The basic aspects recycling of fly ash Despite the current and emerging new technologies and solutions are proposed for processing and disposal of ash carryover, in Russia many of the ideas had actually been implemented at least in any trial version. ... Write a ubiquitous technology, processing every ash was unrealistic.

Oct 22, 2016· Technology of Fly Ash Recycling at CoalFired Power Plants. Authors; Authors and affiliations; ... a combination technology for processing heat and power plants fly ash has been developed, that includes magnetic and electrical separation in vibrofluidized state, providing for a stable production of marketable product with carbonaceous particles ...

SEFA processes and markets environmentally sustainable products derived from fly ash for the concrete industry, recycling over 20 million tons of fly ash in the last 30 years. We are an integral part of some of the country''s most successful coal ash recycling programs.

The effluent treatment process neutralizes blowdown from wet flue gas scrubbers or from fly ash washing and removes contaminants such as heavy metals, ammonia or persistent organic pollutants (POPs). Depending on the plant configuration, some contaminants such as mercury or zinc can be recovered for recycling.

Philip Michael explains an innovative recycling technology which is transforming coalfired power station waste (fly ash) into valuable, ''ecominerals'' on an industrial scale. RockTron''s new plant at Fiddler''s Ferry in Widnes, Cheshire, UK (Fig. 1), has the capacity to recycle up to 800,000 tonnes of fly ash .

By recycling this coal ash in the form of a raw material for cement and construction material, we have greatly reduced its total volume. In addition, some of the coal ash is processed into JISstandard products for outside sale. For more information, please visit the website of Kanden PowerTech Corp., a member of our Group. Fly ash

SEFA has recycled over 20 million tons of fly ash in the last 30 years that would have otherwise gone into landfills or ponds, and we were the first company in the world reclaiming and recycling coal ash from ponds for concrete.

The Oak Creek processing facility is on schedule to achieve its design capacity to process 60,000 tons of sludge and 85,000 tons of fly ash into about 90,000 tons of lightweight aggregate per year.

Fly ash recycling plant to handle 400,000 tpa in South Carolina The SEFA Group will build a 40 million facility to recycle 400,000 tons (362,873 tonnes) of highcarbon fly ash using new proprietary recycling technology...

Handling. The collected fly ash is typically conveyed pneumatically from the ESP or filter fabric hoppers to storage silos where it is kept dry pending utilization or further processing, or to a system where the dry ash is mixed with water and conveyed (sluiced) to an onsite storage pond.

With our new fly ash processing system, we can increase the recycling rate of waste by as much as , step by step. First operator in the Nordic countries We are the first operator in the Nordic countries to treat fly ash in a way that is compliant with the new EU regulation.

The fly ash generated from oil burning is collected with a dust collector installed on a boiler. Recently, The necessity of developing a new process for recycling fly ash has recently received considerable attention due to the rather short life of landfills used for the disposal of a fly ash.

Fly Ash Sales Operations. SEFA is a premier technical product and service company to the construction and utility industries and an innovative leader in fly ash beneficiation. Through partnerships with utility and concrete companies over four decades, we have been recycling fly ash which otherwise would have been disposed in landfills or ponds.

WhatsApp)

WhatsApp)