Rod Mill YouTube

Jul 10, 2017· A rod mill operation principle and inside motion. ... How To Recover Gold From Computer Scrap with Chemicals ... Small production ball mill for ore grinding Duration: 2:42. mbmmllc ...

WhatsApp)

WhatsApp)

Jul 10, 2017· A rod mill operation principle and inside motion. ... How To Recover Gold From Computer Scrap with Chemicals ... Small production ball mill for ore grinding Duration: 2:42. mbmmllc ...

Grinding Mill Gold Ore Grinding Mill Gold Ore Crusher Gold ore mining is The ball mill is a key piece of equipment for grinding crushed materials, gold ore fine grinding mills Gold Mining Process suger Cane grinding Equipment_grinding millgrinding machinegrinder Materials and Appliion of Ball Mill: gold crusher products by products from . ...

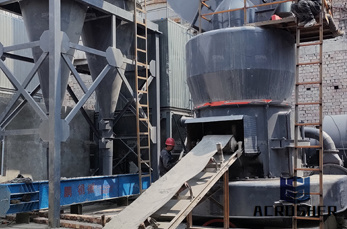

uses of mill grinding machine is ideal machine for grinding barite, limestone, mica, talcum, quartz, calcite, granite, porcelain clay, basalt, gypsum, gold, iron ore, bauxite, copper, cement, coal etc. So it has wide application in powder making industry of construction, mining and papermaking and so on. Quick Way to Get Price

Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation. Image of cut away ball mill, showing material flow through typical ball mill. Flash viedo of Jar Drive and Batch Ball Mill grinding ore for testing.

The grinding process reduces the rock to a slurry. The SAG mill is a large revolving cylinder. Rock is ground by the turning action of the mill, and impact from the hardened steel balls and the rock itself. In order to ensure that the rock is ground finely enough the SAG mill has a trommel screen (5), which acts like a large sieve.

According to the ways by which motion is imparted to the charge, grinding mills are generally classified into two types: tumbling mills and stirred mills. In tumbling mills, the mill shell is rotated and motion is imparted to the charge via the mill shell. The grinding medium may be steel rods, balls, or rock itself.

Ball mills have been the primary piece of machinery in traditional hard rock circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling can be justified by an operation.

Arrastra, simple mill for grinding and pulverizing (typically) gold or silver ore. Roller mill, an equipment for the grinding or pulverizing of grain and other raw materials using cylinders; Stamp mill, a specialized machine for reducing ore to powder for further processing or for fracturing other materials

Gold Recovery. Concentrating Tables; Fine Gold Recovery; Gold Dredges; Gold Wash Plants; Gold Concentrators; Crushing; Classification; Grinding. GRINDING MEDIA; Flotation. Pumps; ... All Laboratory Grinding Mills are presented here. Sort by Default Order. Sort by Default Order; Sort by Name; Sort by Price; Sort by Date; Sort by Popularity; Show ...

Gold ore ball mill gold grinding machine The gold ore milling treatment process is the size reduction of the gold ore particles down to a size giving Get INFO hard rock mining equipment for gold grinding gold ore grinding mill gold ore dressing plant the dry process and the wet processThe gold grinding mill .

grinding media material used for grinding gold ore Know More. grinding media material used for grinding gold oreBall mill ore crusher price The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement grinding media material used for grinding gold ore,grinding machine to grind the ore .

A stamp mill (or stamp battery or stamping mill) is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or for extraction of metallic material down is a type of unit operation

In Fig. is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in. to 108 in., with the corresponding lengths of .

Mar 03, 2015· Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or .

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain .

Grinding in small plants, as in larger installations, has proven to be the most costly of all unit operations from both capital and operating standpoints. Therefore, grinding deserves the most scrutiny of all operations during the design procedure. A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills having between 100 and 1,000 ...

Gold Stryker® GS7000LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation. The Gold Stryker® GS7000LDuses a large 25 HP Honda Industrial engine for many years of trouble free use.

Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill. To prevent the conditions leading to rod charge tangling, the length to .

1 Over the past 15 years, minetomill studies have focused attention on the impact blast fragmentation has on concentrator throughput. Blasting provides the first opportunity for comminution – or size reduction. It is also a cheaper and more efficient process, compared to both crushing and grinding.

Stamp mills are used by miners to crush valuable ore and extract the metals within them. Gold, silver, and copper are common metals that are found within ore, and stamp mills allow these metals to be released from rock for further processing and refining.

Coal was called the black gold and the food of industry, is the major energy since the 18th century. During the Industrial Revolution, along with the invention and application of steam engine, coal is widely used as industrial fuel and brought unprecedented huge productive forces for the society. ... HC1700 Grinding Mill has open circuit system ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

Jun 19, 2015· If 75 percent of critical speed is considered desirable for efficient grinding in a meter (8 foot) diameter mill, then the same will be true for a meter (15½ foot) diameter mill.

Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration (gravity or flotation) or varies, depending upon the type of ore and the amount of reduction required. In addition, some of the older properties continue with methods that perhaps are not considered the best in light of recent improvements but that .

WhatsApp)

WhatsApp)