Balls | McMasterCarr

McMasterCarr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

WhatsApp)

WhatsApp)

McMasterCarr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Jun 12, 2013· Discrete element simulation of Ball Mill, performed with OpenSource Software YADE. https://

closed circuit ball mill closed circuit ball mill suppliers A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing Ball mills are also used in pyrotechnics and the manufacture of black powder, but cannot be used in the preparation it is suitable for open as well as closed circuit grinding and is applicable for materials of all degrees of hardness

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary ...

We currently offer the widest variety of styles of Round Tube Packaging in the industry. For openended clear plastic tubes, our extensive range of diameters and wall thicknesses are available with an ultrathin wall, thin wall or heavy wall. Or, if you are looking for a containerstyle package, select the sealed bottom clear plastic tubes or our telpic tubes or cylinderpaks.

Jun 20, 2019· For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%). Pulp (crushed ore and water) fills another 15% of the drum''s volume so that the total ...

These metal balls have a wide range of applications for the designer and fabricator. They have an ample wall thickness for welding, screwing or tapping. Steel and stainless balls are 11 gauge; and aluminum, and brass balls have a 1/8" wall thickness. Standard finish is mill with the weld seam ground flush. Contact Wagner for polished finish ...

Ball and Tube Mill Opn | Mill (Grinding) Tube, pipe and roll forming mill evaluations ... Forming Mill OnSite. FREE Mill Evaluation. ... not satisfied with our onsite mill evaluation performance in .

Jun 15, 2016· London''s first naked restaurant opened with a waiting list of 46,000. Clothing is optional and technology is strictly forbidden.

Now, the are left without a team to play for. "All of the other leagues in the area are playing, AGSL, Boardman, you name it. We feel these kids should be playing ball.

open ended problem of ball mill machine End Mills Amazon SpeTool 14411 Ball Nose Carbide End Mill CNC Cutter Router Bits Double Flutes Spiral Milling Tool 1/4 inch Shank with 3 inch over Length 5. price End Mill for PCB Machine Pack of 10. by JIUWU. 11 90.

Designed to hold your part on 4 and 5axis milling machines, these vises provide rigid clamping while exposing five full sides of the workpiece. This allows even complex parts to be completed in a single operation. You must cut a dovetail into your material before the vise can grip it.

What Is The Difference Between Ball Mill And Tube Mill. What is the difference between a Raymond grinding mill 0086 371 Ball mill and Raymond mill are common milling equipment in mines, the two have many similarities, also has its different places at the same time, the working principle, structure and application of several aspects of the simple a

Development of a Tubeball Coal Mill Mathematical . A. Modelling Study of Tube Ball Mills 1. Initial Model of the TubeBall Mill The mathematical model of the TubeBall mill was developed based on fluid mechanics; principles electrical engineering, thermodynamics and aerodynamics Wt K A t K A t cfP fP ()=⋅ + ⋅ 11 2 2 (1) As the total mass of coal fed into the mill per hour is ...

These products are manufactured for industrial gears wholesale, sugar mills, sag mills, ball mills, tube mills, coal mills, and sponge iron plants, grinding mills, gold mines and many more. We provide erection and commissioning consultancy support for all the equipment either supplied by .

Have you ever felt organic cotton sheets? The softest sheets in the world! Experience the luxury bedding Loved by 3 Presidents™️ made ethically, priced fairly, and guaranteed to last. Don''t miss our comfortable and sustainable pillows, natural mattress, organic blankets, and more! Free shipping .

Ball consumption varies with the fineness of the product, hardness of the ore, quality of ball, and whether a mill is run in closed or open circuit. The ball, consumption for mills delivering a coarse product, all passing 8mesh and containing 10 to 20 per cent. below 200mesh, the mill being run in open .

Jul 21, 2017· Song Open (feat. Verse Simmonds) Artist Meek Mill; Album Open (feat. Verse Simmonds) Licensed to YouTube by WMG (on behalf of Atlantic Records); Warner Chappell, BMI Broadcast Music Inc ...

ISO9001 Certified PVC CPVC Sch 40 and 80 fittings molded from 1/8 14 inch.

3. Cut the connecting PVC pipe about 2 to 3 inches outside the union where the pipe meets the ball valve body, using a hack saw. Apply silicone lubricant thoroughly over all inside parts of the ...

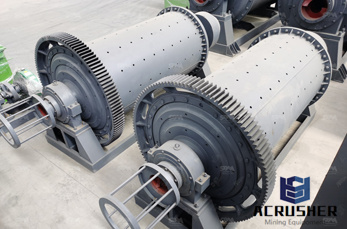

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

The ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill.

1. Consultancy Wing. SOUND OPERATION PRACTICES OF BALL AND TUBE MILL TVNL/TTPS 2X210 MW BY: NTPCCW TTPS SITE THE BALL AND TUBE MILL OF TTPS Lalpania is BBD 4762 TYPE. Where. B stands for BROYER after the name of inventor B stand for French word BOULET meaning balls the main grinding media used for coal crushing.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

WhatsApp)

WhatsApp)