polyurethane thermoplastic grinding equipment

polyurethane thermoplastic grinding equipment Plastic Grinder Jordan Reduction Solutions From plastic pipe, to PVC, or postconsumer plastics, we have the grinding equipment to handle the job.

WhatsApp)

WhatsApp)

polyurethane thermoplastic grinding equipment Plastic Grinder Jordan Reduction Solutions From plastic pipe, to PVC, or postconsumer plastics, we have the grinding equipment to handle the job.

Polyurethane Mill liners Steel, Rubber and hybrids based on these materials are traditionally utilized in Mill Lining to increase the Wear Life and grinding performances of Mills. EUROGOMMA is the only Manufacturer supplying Mill liners wholly constituted by Polyurethane. Why?! .

Reduce power consumtion, downtime and reprocessing with Tega''s advanced range of Metallic Mill lining systems,Composite Mill Linings,Ball Mill Liners, and Grinding Mill liners .

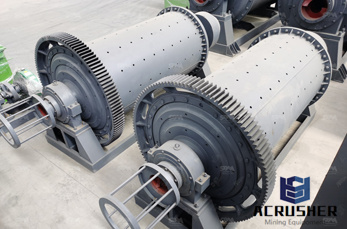

Rubber Ball Mill Liners Plate Ball Mill Liners, Find Complete Details about Rubber Ball Mill Liners Plate Ball Mill Liners,Ball Mill Liners Manufacturers,Rubber Grinding Mill,Grinding Mills from Mining Machinery Parts Supplier or ManufacturerJiangxi Naipu Mining Machinery And New Materials Co., Ltd.

polyurethane liner for grinding mills immobilientessineu. polyurethane liner for grinding mills ecap polyurethane liner for grinding mills trunnion flange b) The internal diameter of the feed end flange or feed end linersTrommel Screens are attached to the end of grinding mills and scrubbers toModular polyurethane panels, each, [Chat Online]

can we use polyurethane liners for ball mills? compared to rubber based liners, what are the advantages and disadvantages of polyurethane liners . ... Use Add New Topic to ask a New Question/Discussion about Grinding. OR Select a Topic that Interests you.

Description: The emphasis on liner design to ensure efficient mill operation has grown, particularly as mills have increased in size. The extent to which a liner effectively protects the mill, imparts energy and controls the mill charge, impacts on the total ownership . Industry Application: Crushers Grinding Mills, Mining, Pipes / Piping

Mining Technology | Mining News and Views Updated Daily is using cookies ... FKK is a rubber, plastic, Vulkollan and polyurethane spare parts manufacturer for local and international projects in the mining, petrol, automotive and marine industries. ... Since 1989, FKK rubber mill liners have provided optimal grinding solutions in major mineral ...

Bradken is a leader in the design, manufacture and supply of mill and crusher liners for primary and secondary applications in the global mineral processing and quarrying industries. We offer our customers complete wear liner solutions for mills and crushers that increase performance, equipment availability and lower maintenance costs.

Patent US Grinding mill liner adapter Google Patents. May 19, 1998 ... A liner assembly for lining a first grinding mill having a first inside diameter, ... consisting of: serenebutadiene, polyethylene and polyurethane.

A wide variety of polyurethane liners options are available to you, such as free samples, paid samples. There are 1,760 polyurethane liners suppliers, mainly located in Asia. The top supplying countries or regions are China, India, and South Korea, which supply 97%, 1%, and 1% of polyurethane liners .

liner''s failure due to oil, ozone, acids or chemical solutions. APPLICATION REQUISITIONS Our Polyurethane Mill Liners can be installed in the following wet grinding mills: Secondary and tertiary ball Mills Primary Ball Mills Rod Mills SAG Mills Via A. Verga 24 127 Bergamo, Italy Tel.: +39 035 261 738

MILLMAST, inmillerected liner suspension mill liner handlers available in maximum liner capacities up to 400kg; RME also has a liner handling solution for the growing number of installations of larger vertical grinding mills. The RUSSELL 3V vertical mill liner handler allows for the safe and efficient transfer of new and worn liners up to 10 ...

Mill linings Linings for grinding mills in the mining and processing industries. We design, manufacture, and market linings for mills. In addition to mill lining using rubber, our product selection includes lining components with steel plate or cast steel reinforcement and with many different types of fixing methods.

The Selection and Design of Mill Liners . Malcolm Powell*, ... the grinding action in mills was published 100 years ago (White 1905 and Davis 1919), the first publication on the influence of liner design on the charge motion only appeared in 70 years later (McIvor 1983). With the advent in the eighties of larger and larger SAG mills running in ...

Roalox AluminaFortified Grinding Jars . ... GRINDING MILL JARS LINED UNLINED ... All sizes have quickchange snapin liners This feature is especially significant when varied materials are milled and cross contamination must be avoided. Using a separate liner for each material protects the product, saves cleanup time, reduces number of ...

Using a separate liner for each material protects the product, saves cleanup time, reduces number of jars required. Note: Cover liners are not snapin; a different cover is needed for use with each liner. Jars are carbon steel. BunaN,EPDM, LowAsh rubber, Neoprene, and Polyurethane liners are available.

Mill liners are designed to be sacial linings to protect grinding mill shells and to enhance the movement of the charge for optimum throughput and grinding performance. A Mill Liner Handler is a purpose designed machine used to remove and insert liners in grinding mills.

When grinding or sanding urethane and generating dust, a dust collector should be utilized. If this is not possible, the operator should properly don and wear an approved dust mask and be sure that a good face seal is achieved. Information courtesy of Polyurethane Products Corporation

Australian Mining Services offer rubber, ceramic lining services – rubber sheeting, screening media, wear linings, Material handling hoses, expansion joints, valves, gaskets, ceramic and composite linings, ceramic wear repair kits, crusher backing

Jan 06, 2019· Lister Rubber Seals for Grinding Mill Liner Bolts PolyTek''s seals are made out of highquality natural rubber designed to handle the most difficult environment. PolyTek manufactures a variety of rubber seals for the mining and aggregate industry. This includes seals used for preventing seepage from a mill liner used grinding mills such as ball mills .

Rubber mill liners. Rubber mill liners Increase wear life and reduce downtime in medium to fine grinding applications (from primary ball milling up to tertiary milling). Liner profiles are designed to fit the mill drilling pattern, optimum ball trajectories for maximum grinding efficiency and optimum liner life.

Mill Linings and Trommels from . is a worldleading supplier of mill liners and trommels. The reason for this is simple. By combining high quality mill linings with service, capital equipment expertise and process knowhow, we can offer solutions that promote safety, improve grinding efficiency, reduce downtime and enhance...

There are basically two groups of Grinding Mill Liners. Ones with a HIGH PROFILE and those with a LOW PROFILE. The high profile liner is designed to give the media the higher lift. This type will be used in mills that are designed for primary grinding and as a result require the impact of the higher cascade. Ball mills working as the secondary portion of a grinding circuit will utilize the ...

WhatsApp)

WhatsApp)