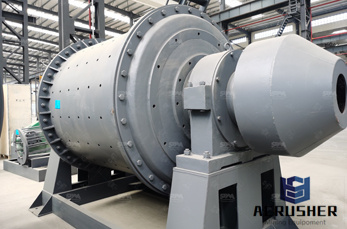

Ball Mill Graph

Ball Mill/Grate Ball Mill/Overflow Type Ball Mill/Rubber ... Shanghai MG is a young and dynamic factory exporting Grate Ball Mill,Overflow Type Ball Mill,Rubber Lined Ball Mill to the overseas market for small to medium customers.

WhatsApp)

WhatsApp)

Ball Mill/Grate Ball Mill/Overflow Type Ball Mill/Rubber ... Shanghai MG is a young and dynamic factory exporting Grate Ball Mill,Overflow Type Ball Mill,Rubber Lined Ball Mill to the overseas market for small to medium customers.

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i...

Cement Production Line cement plant,ball mill,vertical ... CHAENG delivers reliable cement project execution for cement plants using advance cement machinery. With the manufacturing of individual components of cement plants and with fabrication, installation commissioning of entire cement plant, CHAENG has supplied commissioned more than ...

conditions for constant mill sizes and fill factor using two modelling approaches. Satisfactory results will then justify the application of PFC3D as a tool to model the power draw of large scale industrial mills. ... force vector between two balls or ball and wall is composed of .

Report on Ball Sizing. Ball sizing, also known as ball broaching or Ballizing, is the process of forcing an oversize ball through the inside diameter of metal will increase the inside diameter and greatly improve the surface texture of the part. Under ideal conditions, tolerances of one or two tenthouhs of an inch and a mirror like surface can be achieved.

New Shape Milling Bodies for Ball Mills . ... bodies − balls with a diameter of 80 mm, ... Determination of the drum fill factor is influenced by the volume mass of the grinding media [6], [7 ...

The element that rolls the bearing. your global specialist. B/Edition, replaces edition ... – Development of plant lubrication charts ... elements They may be designed as ball or roller bearings, radial or thrust bearings; what they all have in common is the transmission of load and power via rolling elements located ...

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to ...

2 Stoneworking Tools and Toolmarks W Wootton, B Russell, P, PR948_01_05: Carver using a small pick in the Swat Valley, Pakistan, This method is sometimes called the ''mason''s stroke'', It is often used on marble and is very common on softer stones but almost never on granite, [96] The carver can decide at what point to stop this polishing and in the Roman period it was.

grind grinding mill ball manufacturer/supplier, China grind grinding mill ball manufacturer factory list, find qualified Chinese grind grinding mill ball manufacturers, suppliers, factories, exporters wholesalers quickly on, page 5

An increased fill factor will reduce the relative amount of power required to overcome frictional resistance within the charge, and at the contacts of balls and mill shell. Results show that when the fill factor is increased from 5% to 10%, the fraction of power consumed as friction decreases from to for the case of high lifters.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

Energy Savings with Pregrinders Mangalam Cement. with the grinding media and is subjected to compression and shear during this ... The grinding efficiency of ball mill circuit can be increased by removing the coarse ... points in the circuit and analyzed for their particle size distribution (PSD).

Mill sectioning into chambers. Ball separation. Choosing the fill factor and ball grades. Choosing the liner plate profile in each chamber. Choosing the cycle, industrial process scheme, grinding stages, etc. The origin of all drawbacks is the fixed structure of the BM, .

Coal Ball Press Machine. Introduction. Charcoal ball pressure machine means we use briquette machine who has two big rollers to press fine charcoal powder into small ball shape briquettes. The rollers of charcoal ball pressure machine are made of 65Mn, which makes rollers have long service time. Best Performance coking coal powder ball press ...

balls grinding in thane stone crushing plant in thane Newest Crusher, Grinding Mill, Ball Mill Ball mills are used primary for single stage fine grinding, regrinding, . More siddheshwar stone crusher thane CODEP. In this page, you can find crusher,jaw crusher,Impact crusher,CS series cone crusher,vertical roller mill,ball mill,We company . Get ...

Generally, nanoparticles of CH3NH3PbI3 (MLI) powders are increasingly recognized for their applications in solar cells. In this article, a new substitutional path to efficient mass yield with crucial reaction rates was proposed for the synthesis of MLI using a ball milling technique. We compare between the condensation reflux strategy (RM) and the ball milling (BM) technique as synthetic ...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

fill factor chart for ball mill balls. optimum fill level in ball mill rcci. fill factor chart for ball mill balls Crushing Equipment . The optimal ball diameter in a mill 16 Mar New Method to Measure. Theory and Practice for Jar, Ball and Pebble Milling.

fill factor in sag mills ball mill operation issues and solutions uniqueevent. fill factor chart for ball mill balls; purpose of ball mills; onesteel iron bcme crusher ball; ball mill vendor document review checklist; YANACOCHA GOLD SINGLE STAGE SAG MILL DESIGN, OPERATION, AND SAG mill to operate similarly to a large ball mill and achieve Gold ...

fill factor chart for ball mill balls different situations occurring during ball mill oper. fill factor chart for ball mill balls fill factor chart for ball mill balls. ball mill side insert 50 x 9 x 15 mm different situations occurring during ball mill oper; feed mill crushers; chat now. torque factor of ball mill

Dec 23, 2013· Rod mill is similar to ball mills but it uses long rods for grinding media. Autogenous mill is a selfgrinding mill which is used in breakage of larger rocks. SAG (SemiAutogenous Grinding) mill is an autogenous mill which uses grinding balls, it is similar to ball mill .

The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge of various diameters has been observed through the constant of milling rate k in the equation of the grinding kinetics law for the first order grinding R=R 0

ball mills, grinding (steel) balls or pebbles are often added to ... for a range of operating conditions for constant mill size and fill factor using two modelling approaches. fThe discrete ...

WhatsApp)

WhatsApp)