Grinding mill for cement production YouTube

Dec 11, 2016· The famous Vertical Cement grinding mill Design in clinker cement mill process plant,cement production line,cemnt ball mill. grinding in portland cement ...

WhatsApp)

WhatsApp)

Dec 11, 2016· The famous Vertical Cement grinding mill Design in clinker cement mill process plant,cement production line,cemnt ball mill. grinding in portland cement ...

Operation Of Ball Mill Cement Ilgiardinosullagoit. Operation and maintenance of ball mill in cement ball millball mill machineball mill grindingdry ball mills esong cement ball mill is the key equipment for grinding after the crush process which is widely used in the manufacture industries such as .

principles of the grinding process ball mill in cement. Energy conservation technique in cement production process . .. 4 process b is a closed circuit grinding process combining an air separator and a ball mill. animation cement ball mill A ball mill is a type of grinder used to .

Aug 30, 2012· Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 ⁰C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide.

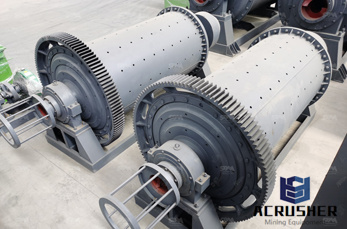

Ball Mill For Cement Grinding Working Principle Ppt. Ball mill Wikipedia. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals.

principles of the grinding process ball mill in cement ... principles of the grinding process ball mill in cement production PRODCUT principles of fine grinding ore dressing principles and practice in scribd indonesia...

Cement Grinder, Cement Ball Mills, Cement Manufacturing ProcessChina There are two kinds of ball mill, grate type and overfall type due to different ways of » Learn More Very few people know the basic Manufacturing Process of High Alumina Grinding Balls, and even fewer people are willing to tell others about how it works.

cement ball mill basic operation principles . cement ball mill operating principle pdf. ball mill for cement grinding working principle ppt. download as pdf. cement grinding is the single biggest consumer of electricity in the manufacturing process .o for ball mills, only of absorbed energy is utilized in surface production, . Read More >>

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

Cement ball mill principles rajcatererscoin. A ball mill is a type of grinder or mill used to mill the materials into fine powder Description, Parts,Construction, Ball Mill Working, Principle, Ball Mill Types, and The ball mill is a key equipment to grind the crushed materials and cement, Ball Mill Maintenance Seminar the Ball Mill. Oline Chat

Method of balls rolling on ball rolling mills is one of the most modern production methods. Transversal rolling of balls from the round billet is economical. It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 1015% to ...

Ball mill > Grinding > Cement Manufacturing > Cement Industry ... Grinding and Drying Ball mill ... highpressure grinding roll, the ball mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding. ... ball mills represented a new departure from ancient grinding process principles, and ... The ball mill by ...

Mills belong to a class of equipments that accomplish comminution of materials in the fine range. There are two types of mills which are mostly used in cement plants for grinding raw mix viz. Ball mills and VRM. Ball mills Ball mills are essentially fine grinding units capable of grinding material to a fineness say 84% passing 90 microns.

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc ...

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder.

consumption, production capacity and cement quality are given. A case ... has been increasing for reasons concerned with process economics, energy ... pregrinder in cement grinding circuits operating with ball mills to reduce the ... In this chapter, operating principles of highpressure grinding rolls, Horomill®, vertical roller. Get Price

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Lvssn provides various grinding equipment for cement production line, including: Grinding mill,Ball mill,Rod mill,Roller press,Veritcal mill,Pipe mill

In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given. A case study performed on a typical energyefficient Horomill® grinding ...

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

advantages of ball mill cement careereduin Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory [More info] Get More; Ball Mill: Operating principles, ponents, Uses, Oline Chat

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

Overview. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

WhatsApp)

WhatsApp)