grinding mill power calculation

1 modeling the specific grinding energy and ballmill ... the calculation of the specific grinding energy w and. the determination of the mill power draw P. .

WhatsApp)

WhatsApp)

1 modeling the specific grinding energy and ballmill ... the calculation of the specific grinding energy w and. the determination of the mill power draw P. .

Modelling SAG milling power and specific energy consumption including the feed percentage of intermediate size particles M. Silva, A. Casali⇑ Mining Engineering Department, Universidad de Chile, Beauchef 850, Santiago, Chile

We propose a new model for the prediction of the specific grinding energy, which proved to approach very well the values calculated with the help of the Denver slide rule. The proposed model, combined with a model giving the ballmill power draw, is used for the ballmill scale up.

in the study by providing operating data for 3 semiautogenous grinding (SAG) mills and 4 ball mills. The development of the model was based on an article by Radziszewski (2013) suggesting identifying energy losses during grinding using a thermodynamic model. This approach was used to estimate the heat dissipated by the

Grinding performance is evaluated mainly in terms of specific grinding energy. The number of active grits per unit area and their slope is considered as the two grinding wheel topographical key parameters for studying grinding performance. To provide a view on how various parameters influence specific energy and the importance of wheel topography and grit workpiece interaction, a specific ...

The ball mill modeling has shown that depending on the coal and dust characteristics the maximum possible grinding capacity of the mill is reached at the level of 80 to 95 per cent of the maximum possible loading of the mill with the material being ground (Pistun et al., 2002). ... Modeling the specific grinding energy and ball mill scaleup ...

BM = Ball mill specific energy from T 80 mm to final product P 80, using Bond''s Law, (kWh/t) W T = Total grinding mill circuit specific energy (kWh/t) Note that K BM is the composite of EF3, EF4 and EF5 factors for ball milling (Rowland, 1982). Morrell and SMCC Morrell (2004) developed a methodology for predicting specific energy with

base case, the existing circuits were fitted and simulated using a JK SimMet® model. Specific energy requirements for the proposed HPGR ball mill circuit and HPGR stirred mill circuit were determined from a pilotscale HPGR and stirred mill test, in association with a .

SPECIFIC COMMINUTION ENERGY General This model uses the equations published in the following 2 papers which the user is encouraged to read: MORRELL, S., 2010, Predicting the specific energy required for size reduction of relatively coarse feeds in conventional crushers and high pressure grinding rolls, minerals engineering Volume 23,

2 MODELLING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP Ballmill scale up (Bond''s Law)Data: zBond work index w i zFeed D f and product d size (both 80% cumulative passing) Result: The specific grinding energy w Mill power draw P = wT, where T the mill capacity Mill dimensions (from Tables or charts)

J. Drozdiak is with Hatch in Vancouver. This article is adapted from a paper, Energy and Cost Comparisons of HPGRbased Circuits with the SABC Circuit Installed at the Huckleberry Mine, they presented at the 45th Annual Canadian Mineral Processors Operators Conference, which took place in Ottawa, Ontario, January 2224.

Mill related stress model The grinding behaviour of a mill is determined by ... = Specific energy input into grinding chamber E m,P:= Specific energy transferred to product particles ... Effect of friction coefficients on grinding ball motion e =

Calculation of energy required for grinding in a ball mill. The Bond work index, Wi, as an indicator of the grindability of raw materials is not a material constant but rather it changes with change of size of the grinding...

MODELING THE SPECIFIC GRINDING ENERGY AND BALL . 2 MODELLING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP Ballmill scale up (Bond''s Law)Data: zBond work index w i zFeed D f and product d size (both 80% cumulative passing) Result: The specific grinding energy w Mill power draw P = wT, where T the mill capacity Mill dimensions (from ...

Highlights Modeling of specific grinding energy for two different materials done. New method of single grit scratch test used. Four main components of specific grinding energy analyzed. Specific ploughing energy found to be most significant component. Model helped to explain concept of size effect.

38VSPs (with the grinding media of balls and tread rollers, respectively). The classical energysize 39reduction model is modified with the addition of particle size in the exponential form to compare 40the grinding energy efficiency (product fineness for the certain specific energy) of two labscale 41mills.

Modelling and Scaleup of High Pressure Grinding Rolls ... This paper aims to provide a review of the modeling of high pressure grinding rolls. ... Modelling the Specific Grinding Energy and Ball ...

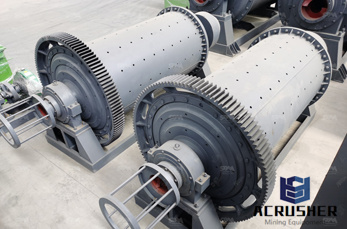

Ball mill grinding kw. Modeling the specific grinding energy and ball 2 modelling the specific grinding energy and ballmill scaleup ballmill scale up bonds lawdata zbond work index w i zfeed d f and product d size both 80 cumulative passing result the specific grinding energy. View All; Ball mill grinding process pdf

Monosize grinding tests in a laboratory ball mill were performed to determine breakage parameters, with different ball diameters. A model was developed to determine the specific rate of breakage in terms of the system rheology. With this model, it was demonstrated that an increase in suspending fluid

Throughout the batch grinding tests, the power draw of the mill was measured using a purpose built power meter to facilitate the calculation of specific grinding energy. Results Table I shows the Bond ball mill work index obtained for the ore samples as well as the iron and silica content in concentrate and tail after LIMS. The concentrate weight

Even though semiautogenous grinding mills and ball mills are normally used in grinding processes, the industry is driven to decrease cost by increasing efficiencies and decreasing energy consumption. High Pressure Grinding Rolls (HPGR) are seen as an energyefficient alternative but their developments in modeling and control have received ...

during Grinding of Quartz with the Use of Population Balance Modeling † Evangelos Petrakis*, Elias Stamboliadis and Konstantinos Komnitsas 1 Technical University of Crete, School of Mineral Resources Engineering, Greece Abstract It is known that ball milling is an energy intensive process and great efforts have been made over the years to

As a first step approach to upgrading the ball mill model, a specific energybased size reduction model for a batch grinding ball mill was developed, in which no mass transport or discharge mechanism occurs, and the product size distribution solely represents the size reduction results.

modeling the specific grinding energy and ballmill scaleup. and product d size (both 80% cumulative passing). Result: The specific grinding energy w.

WhatsApp)

WhatsApp)