Bowl Coal Mill 493 C E Raymond Bowl Mill MC

493 Raymond Bowl Mill Wabash Power6 (Six) Reconditioned #493 CE Raymond Bowl Mill Coal Pulverizers rated at a base capacity of 16,800Lbs/Hr on 55 grindibilit

WhatsApp)

WhatsApp)

493 Raymond Bowl Mill Wabash Power6 (Six) Reconditioned #493 CE Raymond Bowl Mill Coal Pulverizers rated at a base capacity of 16,800Lbs/Hr on 55 grindibilit

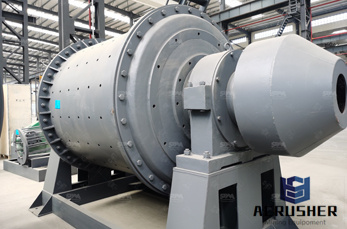

BOWL MILL Bowl mills are employed to pulverize the precrushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion. The operating characteristics of bowl mills make it the best mill available for the direct firing system of the coal.

Dec 13, 2011· A vertical spindle mill is also designed for pressurized and suction type requirements. Boiler designers use this type of mill for poor quality coal as this type of mill rejects foreign materials like stones and other high density materials. The power consumed by the mill per ton of coal ground is only twothirds of the ball mills.

Comments of Of Coal Power Plant And Ball Mills Bowl Mill; COAL MILLS FOR THERMAL STATIONS blogspot. Dec 13, 2011 · The power consumed by the mill per ton of coal ground is only twothirds of the ball mills However if the primary air fan power is also taken into account, in the case of a pressurized mill the power consumption is lower only by about 15%

RAYMOND® HP BOWL MILLS arvosgroup. Raymond Bowl Mills: With over 5,000 units in place worldwide, the bowl mill is considered by many to be the finest machine available for pulverizing coal and pet coke as primary fuel for firing kilns, air heaters and other process equipment It provides a safe, efficient means of uniformly pulverizing and drying these fuels The HP mill.

Bowl Mill s Raymond® Bowl Mill. The Raymond® Bowl Mill is considered the finest vertical roller mill available for pulverizing coal. With the high cost of fuel, many companies are discovering that it is increasingly cost effective to utilize coal or petroleum coke as primary or alternative fuel for firing kilns, air heaters and other process equipment.

bowl mills grinding seattle wa city; difference between vertical grinding mill and bowl mill; manufacturers of centrifugal bowl gold concentrator india; hp936 bowl coal mill; cone crusher bowl liner; bowl mill giling mangkok; principle of cement quality of verical mill; pictures of coal power plant and ball mills bowl mill; coal crusher hp 803 ...

Dec 13, 2011· Bowl mills are used for pulversing coal in pulverized coal fired boilers. The coal to the mill is fed by a coal feeder from the coal bunker. There are many type of feeders used for coal feeding like the belt feeder which can be in volumetric or gravimetric mode, the chain link feeder, the drag feeder, etc. Row coal from the yard is sized in crushers and stored in coal bunkers.

Reconditioned 372 CE Raymond Bowl Mill Coal Pulverizer rated at a base capacity of 6,200 Lbs/Hr. on 55 grindibility coal pulverized to 70% minus 200 mesh. Mill is capable of grinding down to 90% minus 200 mesh as well as grinding a 40 hardgrove but at a lower rating.

Mar 03, 2014· To prevent coal entering in to the Gear case, an air sealing system is provided. Hot primary air for drying and carrying pulverized coal, enters through insulated Mill side and Liner Assembly. Tramp Iron, pyrites and stones coming in the mill with raw coal move out of the bowl and being heavy, fall into the mill side and linear assembly.

drawing of a raymond mill coal pulverizer in india – Crusher . the allround manual for a raymond bowl mill. the and other crusher the company in india small iron ore coal .

Coal Mills Service Solutions. We are a world leader in coal pulverizing and overall mill performance. with a wide portfolio of services offering covering both horizontal and vertical boiler mills.

This is a used Raymond Bowl Mill Journal For Sale. It is for sale due to a plant shut down and will be located in Belgium, Wisconsin ready to ship. Save Thousands .

Restore bowl angle (J) to the original design angle, typically 20 degrees plus or minus 1/2 degree. ... Mill power to ton of coal throughput. In general, when the mill draws more power per ton of ...

The Raymond brand is considered the gold standard for pulverizing coal and minerals. Wabash has been an industrial leader for over 40 years supplying refurbished mills and components for a variety of industries including cement, lime, mineral aggregates and power generation worldwide. ... Bowl Mills Roller Mills Impact Mills ...

May 07, 2019· A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steam ...

We specialize in coal mills: in particular performance upgrades to meet the increasing demands on South Africa''s power generation industry. We provide a comprehensive service for major milling plant modifications, including investigations, feasibility studies, design, manufacture, installation and .

Combustion Engineering 783RP BowlMill Coal Pulverizer. enclosed chamber with wear resistant plates. The hammers impact on the coal, crushing it against the plates. Further pulverization is achieved as the smaller coal particles are ground through attrition against each other

Dec 13, 2011· Bowl mills are used for pulversing coal in pulverized coal fired boilers. The coal to the mill is fed by a coal feeder from the coal bunker. There are many type of feeders used for coal feeding like the belt feeder which can be in volumetric or gravimetric mode, the chain link feeder, the drag feeder, etc. Row coal from the yard is sized in crushers and stored in coal bunkers.

Jul 10, 2016· bowl mill working principle pulveriser to dry the coal, sufficient pressure on the rolls to pulverise it, and proper setting of the classifier deflector vanes to obtain a fineness reasonably close to that for which the pulveriser was Experience will

The Raymond® Bowl Mill is considered the finest vertical roller mill available for pulverizing coal. The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and classify solid fuels to 95% passing 200 mesh (<5%R75μ) with a wide range of capacities from 24 to 150 stph.

Monitoring and Diagnostics. Data Collection The RollBowl COP system contains the software and hardware necessary to collect and analyze coal pulverizer operating data, using both timedomain and frequency domain techniques, to reveal the dynamic conditions present within the mill without removing it .

Nov 15, 2016 Coal mills use static or dynamic pneumatic classifiers to select the correct cut size and consistency for combustion. The feed flows directly into the mill which has variable speed rotating table and two rollers supported by adjustable hinged spring lever arms that rest clear of .

The RollBowl COP system contains the software and hardware necessary to collect and analyze coal pulverizer operating data, using both timedomain and frequency domain techniques, to reveal the dynamic conditions present within the mill without removing it .

WhatsApp)

WhatsApp)