China Cement Mill, Cement Mill Manufacturers, Suppliers ...

China Cement Mill manufacturers Select 2019 high quality Cement Mill products in best price from certified Chinese Mill manufacturers, Grinding Equipment suppliers, wholesalers and .

WhatsApp)

WhatsApp)

China Cement Mill manufacturers Select 2019 high quality Cement Mill products in best price from certified Chinese Mill manufacturers, Grinding Equipment suppliers, wholesalers and .

Cement production line is the construction project to produce cement by a series of equipment. LVSSN group adopts advanced technology and equipment to improve the efficiency technical level advanced design ensure the economical investment for the cement production line.

offers 2,763 high efficiency ball mill products. About 58% of these are mine mill, 14% are grinding equipment, and 1% are other fabrication services. A wide variety of high efficiency ball mill options are available to you, such as ac motor, dc motor, and stepper motor.

Dec 03, 2018· High Efficiency Cement Grinding Mill Machine Video ... Yuhong Heavy Machinery is the professional manufacturer of cement grinding mill, It is mainly used in mines, nonferrous metals and non ...

Highefficiency cement grinding ... a reduction in specific power consumption of around 50 per cent compared to conventional ball mill circuits is achievable. The high compression stressing applied inside the material bed in a HPGR is distinguished by its significantlyhigher degree of energy utilisation in comparison to the frictional and ...

Grinding system at [0017] 0 13m open to the flow of production cement mill, two kind of cement was tested in the actual production, and without adding adding production aids actual operation index and cement performance statistics, table 2 and table 3 respectively. ... Highefficiency composite cement ballmilling ...

Getting more from the cement ball mill with the ... installing a high efficiency classifier is to increase the mill efficiency, with a consequent increase in mill through ... a classifier of an older generation. The high efficiency classifier allows an increased feed of fresh material to the ball mill by avoiding the return of fine material to ...

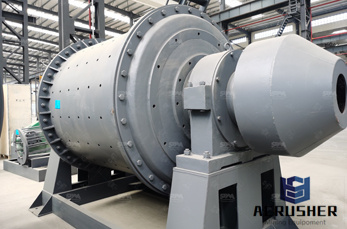

Dry ball mill is widely used in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry. Working principle: Ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and ...

High efficiency ball mill for cement grinding News Date: 10:14:49. High efficiency cement ball mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in chemical, metallurgy, and power industry and so on.

Cement ball mill is mainly used for circle flow grinding system, and it has the characteristics of high efficiency, big capacity, and low power consumption, especially for cement slag. Compared with traditional ball mills, it can increase 1520% of capacity and 10% of electricity, otherwise, the temperature of final products can lower than 20 ...

Industrial planetary mill for cement is a new type of highefficiency nondeadpoint mixing equipment. It has a unique and novel mixing form. There are two or three multilayer paddle mills and one or two automatic scrapers in the container.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills. Hot Sales High Performance Cement Mill Manufacturers ...

Better product quality can be achieved as compared to the ball mill product due to the better options for separate grinding. For example, in additive cement production, the blast furnace slag has to be ground to Blaine values of 5,000 cm 2 /g. Water demand and setting times are similar to that of a ball mill cement under comparable conditions .

The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on Our company has more than 40year experience on the manufacture of cement ball mill, the quality of our product takes a ...

Cement ball mill is an important fine grinding equipment. It has the characteristics of high efficiency, energy saving, environmental protection and large production capacity.

Mar 05, 2017· offers 2,763 high efficiency ball mill products. About 58% of these are mine mill, 14% are grinding equipment, and 1% are other fabrication services. A wide variety of high efficiency ball mill options are available to you, such as ac motor, dc motor, and stepper motor.

offers 926 high efficiency cement mill products. About 56% of these are mine mill, 9% are cement making machinery, and 3% are grinding equipment. A wide variety of high efficiency cement mill options are available to you, such as ball mill, raymond mill.

Mar 08, 2013· re CALCULATION OF BALL MILL GRINDING EFFICIENCY. Please can anyone give me, step step by procedure on how to work out on cement ball mills to. improve it''s efficiency, optimum operation and increases output.

High Efficiency Ball Mill From Shanghai (manufacturer, high efficiency ball mill from zhongzhou manufacturer,General Introduction of Ball Mill:Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground The rotation is usually between 4 to 20 .

Jul 23, 2015· High efficiency cement cooling for cement milling ... Ball Mill Critical Speed Working Principle ... Working principle of Ball Mill /ball cement milling machinery plant Group ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Telephone: Contact Person: Fax:— In the production process of cement ball mill, the mill is one of the key equipment for manufacturing cement. The power consumption of the mill accounts for...

information on ball mills. ... To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being ... Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Read More

Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with...

WhatsApp)

WhatsApp)